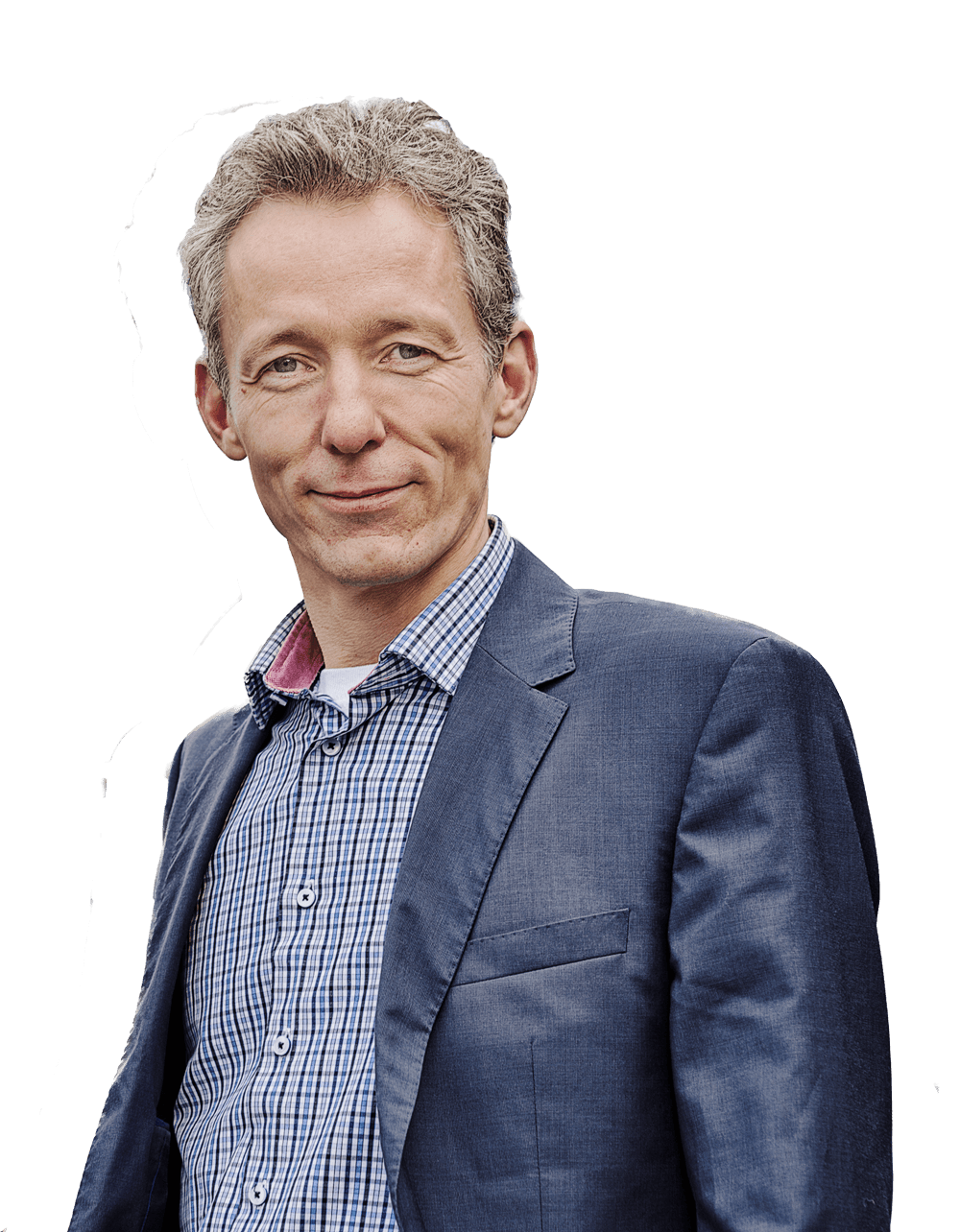

SYSTEMATIC CAN PROVIDE YOU WITH A COMPLETE TURN-KEY IC SOLUTION

Innovation is a catalyst for your growth and efficiency. We help enterprises move faster, and startups build smarter. Accelerate your product releases by relying on our highly-qualified engineers to develop the most optimal custom IC solutions for your business, and our full support to take this to production.

✓ Enhance competitiveness with our in-depth technological knowledge and practical solutions

✓ Honest advice on selection of process and foundry to meet the product requirements technology-, cost- and timescale-wise

✓ Advanced technical advice and support on product enhancement and product definition

✓ Transparent, flexible and competetive IC product development in full cooperation with customer

✓ Full support beyond GDSII tape-out: production steps, qualification, supply chain management and delivery

✓ Benefit from our international network of expert partners

EXPERTISES AND INDUSTRIES

You need a trusted partner in developing A-Z of a competitive ASIC? Avoid future challenges and leverage our decade-long expertise in custom IC design and development. Having helped companies like NXP, Broadcom, Panasonic, Melexis and OSRAM with custom solutions, we know what defines success across industries.

Sensor interfacing

We perform world-leading research in sensor interfacing and create groundbreaking innovations in multiple domains.

Integrated power

The combination of our widely acclaimed and profound integrated power expertise is what makes SystematIC unique.

High voltage

Thanks to our experience in high voltage technologies, we can design accurate ASIC’s for special high-voltage applications in less time and at lower costs.

THE SYSTEMATIC APPROACH

SystematIC , as its name aptly suggests, draws its strength from a thorough systematic development methodology and a profound knowledgebase which it applies in practical implementation of every analog and mixed-signal ASIC it develops. Thanks to the ‘SystematIC’ methodologies fully functional and on-spec silicon is attainable with a minimum number of design iterations, resulting in a significantly reduced overall development time.

Our complete turn-key solution provides customers with the most efficient path from specification through to medium and high volume ASIC supply. Combining decades of experience we ensure high performance and high quality ASIC solutions are developed and brought to production for you.

For our turn-key product developments we support the full package of IC development services, phase 1 to 3, and continue with production, supply-chain and product support in phase 4. We can supply wafers, post-processed and/or tested wafers or assembled and tested ASICs, completely adapted to your production needs.

PREPARATION

Feasibility, product definition, development plan (steps, schedule, efforts, tools, costs)

Will the idea work?

What is the best system topology?

What is the most suitable technology?

What development plan can we support?

- Investigate the idea with consideration of the laws of physics and limitations of integration technologies

- Fundamental comparison of different implementations or architectures of the system function(s)

- Address risks and uncertainties:

- can a discrete (PCB/FPGA) prototype help to reduce these?

- how do we model special or external components (sensors, actuators, transformers, etc.)

- Consider optimization directions of the performance: The best compromise is based on balancing different aspects (power versus signal-to-noise, accuracy versus area, etc.).

- Consider process requirements, based on functionality, performance and chip area/price and select appropriate IC technology

- Model the system and simulate and confirm system behavior.

- Complete IC definition, including architecture, specification, block division

- Proposal for a SystematIC Design and Development and Production plan.

DEVELOPMENT

Design, simulation, layout, verification, tape-out, evaluation, design adjustments.

Account for production requirements like DfT, ESD, chip area, etc.

- Project management to execute Design and Development plan

- Block-level design, simulation, verification, layout, post-layout simulation

- Top-level design and verification (incl. appropriate block-level modelling)

- Top-level layout and verification

- Peer reviewing and design reports

- Tool selection and installation, including industry standard tools like Cadence and/or Mentor

- Design for testability, support for (external) wafer test and final test engineering

- Application-level verification (simulation, validation)

- (Prototype) Evaluation plan and execution or support for that

TRANSFER TO PRODUCTION

Support data for production (gds2, testplan, etc.)

Connect to production partners

Application support

Preparation for production is an essential element in previous phases already. We take the full responsibility for the steps needed to cooperate with selected production partners and bring the ASIC to release for production.

- Collection and transfer of relevant data to production facilities:

- Physical data: gds2, bond-out, package, etc.

- Data for testing: test operation (testbus), test limits, test plan, yield expectation

- Production (Foundry) options and monitoring:

- Mask options (MPW, SLM, MLM)

- Process options (EEPROM, MIM caps, etc.)

- PCM data

- Test options (wafer test, final-test, both or none)

- Yield optimization

- Test-time optimization

- Qualification support

PRODUCTION and SUPPLY CHAIN MANAGEMENT

From order to delivery

Product support

After customer-approved release for production and product delivery agreement, SystematIC supports

- Responsibility from production order to product delivery: order management and follow-up

- Customer-specific delivery and quality agreements

- Selected production partners are ISO 9001 certified

- Periodical audits of the subcontractors

- Production quality control

- Returned parts investigation, Failure Analysis support and reporting

- Application/Product support

- Test cost and yield optimization

25

YEARS IN BUSINESS

with clients across the globe

85%

RETURNING CLIENTS

approach us for their next IC development

50+

PRODUCTS IN MASS PRODUCTION

to improve your day-to-day life

EXPLORE OUR CHALLENGES AND SOLUTIONS

For over 20 years we've been working as a IC innovation partner to small and big enterprises and technology changers. Our team of professionals provides them with a full range of consultancy, design and development services for Application Specific Integrated Circuits. ASIC's that we build help the world's leading brands transform their businesses, enhance their portfolio's, improve time-to-market and increase their revenues.

Industrial, Automotive, Sensor interfacing

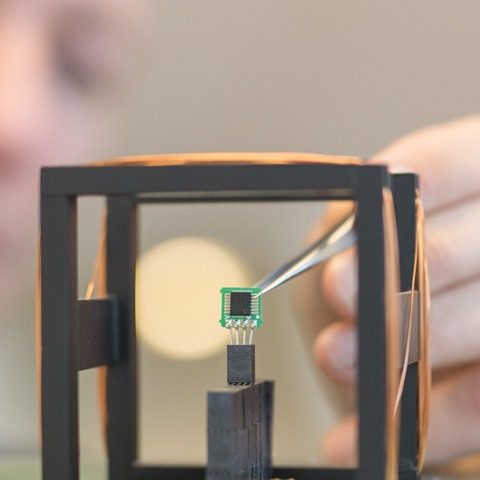

INTEGRATED MAGNETIC SENSOR

![]() 8 weeks: design start to prototype silicon

8 weeks: design start to prototype silicon

Our customers is the Isolation Products Division of a semiconductor leader, who has a strong portfolio based on optical isolation techniques. Application of this fully integrated single chip magnetic sensor opened a new line of magnetic isolation products. Based on our reference high speed magnetic design in 2 months’ time a 180nm CMOS prototype was shipped.

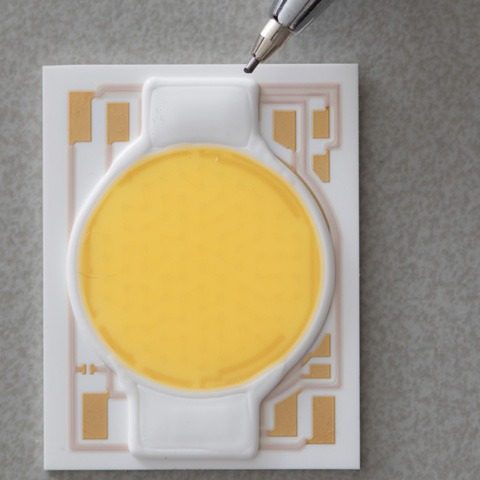

Consumers, Integrated power

AC LED DRIVER IC

![]() 3 weeks: discrete prototype demonstration, 3 weeks: IC definition, process selection

3 weeks: discrete prototype demonstration, 3 weeks: IC definition, process selection

Our customer produces a range of AC LED modules for lamp manufacturers. The products were originally built with discrete components, a different set for each module type. For performance enhancement and simplification of production steps and supply chain, the customer was looking for a custom ASIC solution. The customer was also expecting improved performance on TRIAC dimmer compatibility and a reduction in product costs. With a programmable high-voltage ASIC and only a few external components (rectifier, fuse and surge) all module types can be made. LED modules with such an ASIC are directly driven from the AC mains voltage, are low-cost and are very compact and reliable. An electronic solution was created that made the customer AC LED lamp compatible with TRIAC dimmers. A discrete prototype was built and demonstrated to the customer just a few weeks after the first contact. The discrete electronics where chosen such that they could be implemented in a HV IC process.

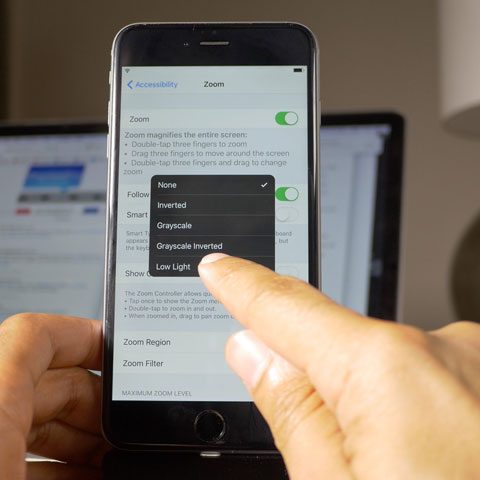

Consumer electronics, Sensor interfacing

PROXIMITY AND AMBIENT LIGHT DETECTION

![]() 3 months: custom ASIC tapout

3 months: custom ASIC tapout

SystematIC has designed a family of products which combines Ambient Light Sensor (ALS) and Infra-red Proximity Detection Sensor (PS) in a single SoC. The ambient light sensor matches the response of the human eye. The infra red proximity sensor measures the distance to an object. Our client is a leading global organization providing components to mobile phone manufacturing companies.

WE GLADLY INVESTIGATE THE POSSIBILITIES FOR A QUICK DEVELOPMENT OF YOUR IC PRODUCT

If you have any remarks or questions regarding our products or our services, please fill in the form or contact us by e-mail or by phone.

SystematIC (HQ)

Elektronicaweg 20

2628 XG Delft

The Netherlands

Phone: +31 15 2511100

E-mail: contact@systematic.nl